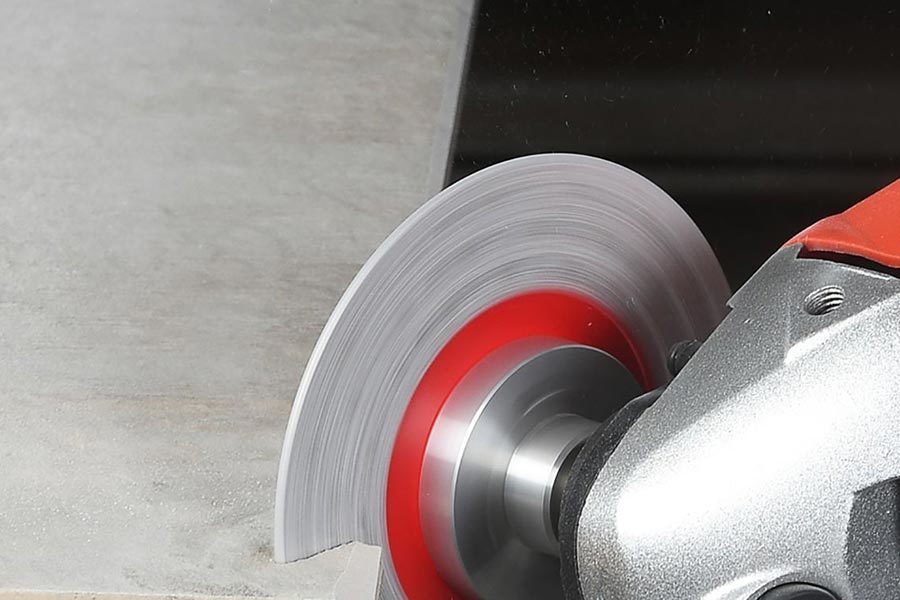

Circular Saw Blade Buying Guide

Release Time:

Jul 21,2023

You most likely already understand that tooth count is essential. When selecting blades, you'll intend to consider these 3 elements: the material you're developing with, the surface high quality you want,

Tooth Count

You most likely already understand that tooth count is essential. When selecting blades, you'll intend to consider these 3 elements: the material you're developing with, the surface high quality you want, and also your allocation of this build. It's recommended that you have multiple blades-- among each sort of tooth count as listed below-- as the various tooth counts serve different purposes. The following is a good guide for tooth count:

Less than 30T = Rougher (hole) cuts

Between 40 to 50T = Mix cuts

Above 60T = Crosscuts

Make & Design

The standard kind for all blades is its circular shape, which is reduced from a piece of plate steel prior to being warm dealt with. Nevertheless, the specifying aspect of top quality is whether your blade body is tensioned. A tensioning procedure will certainly develop a small however visible ring in the blank between the arbor opening for the saw arbor and also the teeth. This operation promotes equilibrium as well as true running while placed to your saw. Other procedures such as noise decrease slots are a bonus offer, particularly if you are running the blade for longer periods.

Hook Angle

You might ask: what is a hook angle, as well as why it is essential? This angle is basically exactly how aggressively the blade tooth exists to the product-- with the aggression raising as the angles obtain bigger. For instance, a more aggressive hook angle (20 degrees) on tearing blades assists you to break down products faster, while blades made for high-end sheet items or non-ferrous metals have a more calm blade angle (5 degrees to 0 levels, specifically). This slows the reducing action somewhat as well as generates a finer finish.

At a lot of basic levels, the hook angle is how the reducing tip of the blade exists to the product. You could argue that this tiny, typically neglected specification is the most essential.

Tooth Geometry

The teeth on your blade do the cutting-- as well as like any type of cutting tool, their layout is crucial to efficiency and finish. When you make use of a blade that not only has the ideal variety of teeth, yet likewise has the proper geometry will certainly give you the results you require in regards to top quality and rate. There have to do with a half-dozen typical grinds that fit a wide variety of tasks, the sort of cut to the kind of material you're reducing. A lot of blade product packaging has recommendations for blade use. Simply match the blade to the material you're using.

Keywords: