How to Make Circular Saw Blades Last Longer?

Release Time:

Jul 21,2023

Although the blade is idle the vast majority of its useful life, it doesn't mean it can't get worn when not in use. Steel corrodes, so moisture and humidity will degrade it.

STORE CIRCULAR SAW BLADES IN A DRY AREA

Although the blade is idle the vast majority of its useful life, it doesn't mean it can't get worn when not in use. Steel corrodes, so moisture and humidity will degrade it. Particularly on more expensive blades, consider removing them and keeping them dry when not in use. This goes for the workshop and especially on job sites. Any time you can remove a blade from excess humidity and store it in a dry area, you win. This increases the length of time your carbide teeth will retain their optimal edge.

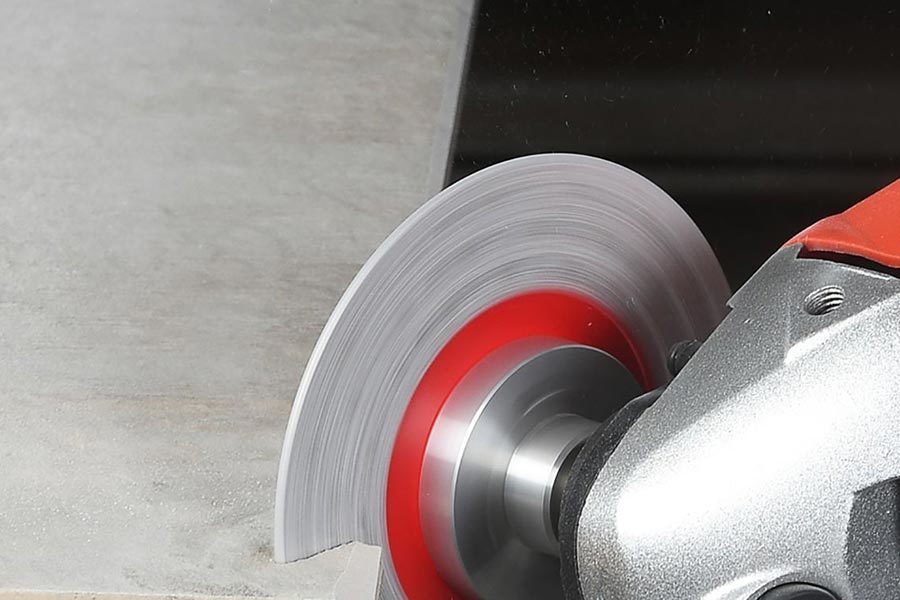

CIRCULAR SAW BLADES LAST LONGER WHEN YOU USE THE RIGHT ONE

Many circular saw blades are billed as the one to rule them all, but different blades are truly suited to different applications. Preserve the blade's life and make it last longer by using it appropriately. Don't cut steel with a standard carbide blade. Don't take a fine-tooth blade and cut laminate when you can get a specialty blade that will do the job for less.

HANG CIRCULAR SAW BLADES THROUGH THE CENTER HOLE

Don't let the blade's kerf rest on the ground but hang a blade through its center hole for temporary storage. This can be as simple as a nail or screw in the wall, but at least the blade won't be dulled by the floor or a shelf. This may seem minor, but all those scrapes and dings eventually take their toll.

CONFIRM THE BLADE GUARD WORKS

Many floors have been damaged, cords cut, and toes endangered when a circular saw's blade guard failed to cover the spinning blade after a cut. It's another good reason to inspect your tools. It also pays to consider a circular saw that includes an electric brake. Most electric brakes stop the blade from spinning in 2 seconds or less.

CLEAN BLADES WITH A NYLON BRUSH AND SOLVENT

Grime can accumulate on a blade. This slows down the cut noticeably and also promotes burning. Clean it every so often with a nylon brush and gentle solvent to refresh the carbide teeth and expose gullets. Try the solvent on a small area first though – some blades have a coating that can come off if you use too harsh a chemical.

Keywords: